Project Highlights:

- Large volatile organic compound (VOC) release affecting soil vapor and groundwater

- PCE concentrations in groundwater in excess of 1,000,000 µg/L

- On-site and off-site soil and groundwater characterization

- Installation of 29 triple-nested soil vapor extraction (SVE) and groundwater monitoring wells

- SVE pilot testing and design and installation of 1,500 cfm SVE system

- Deep multi-aquifer groundwater investigation

- Bench-scale and in In-Situ Chemical Oxidation (ISCO) pilot tests in groundwater

- Institue successful full-scale ISCO remediation

- Coordination and management of off-site agreements

- Membrane interface probe (MIP) investigation

- Evaluation of ongoing comingled plume

- Vapor intrusion investigation

- Fate and transport modeling

- Coordination of multifaceted group consisting of attorneys, responsible parties, and consultants

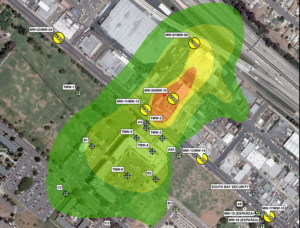

A high-profile environmental attorney referred EEC Environmental (EEC) to a major real-estate developer based on EEC’s experience with investigation and remediation of large-scale VOC releases. Initial testing indicated that groundwater was impacted with tetrachloroethene (PCE) concentrations in excess of 1,000,000 micrograms per liter (µg/L). A groundwater production well was located approximately 0.25 mile directly downgradient of the project site. Concerns at the site included groundwater contamination, vapor intrusion, and widespread soil impacts.

The site is located directly upgradient of a former aerospace facility, which has documented chlorinated solvent releases, thereby introducing a comingled plume element to the project. EEC initiated site assessment activities, including assessment of the lateral and vertical extent of VOC contamination, and forensic evaluation of the PCE to differentiate sources. The initial stages of the project included the installation of an extensive SVE remediation and groundwater monitoring network. Following assessment of the plume, EEC’s engineers designed a 1,500 cubic-foot-per-minute (cfm) soil vapor extraction SVE system to begin remediation of the impacted soil and mitigate vapor intrusion concerns at adjacent properties.

EEC’s construction personnel trenched, piped, and installed the SVE system in stages to accommodate the tenant’s business operations and to avoid conflicts with the holiday shopping season. EEC’s ability to perform the work as a complete design-build contractor resulted in significant savings to the client while maintaining a strong relationship with the regulatory agencies. The continuity of a single contractor from initial site investigation through the remedial process has resulted in a very successful project both technically and in regard to relationships with regulators, tenants, and the community.

After completing appropriate bench-testing and field ISCO tests, EEC successfully implemented full-scale groundwater remediation using potassium permanganate, with concentrations dropping over two orders of magnitude in the first month.

EEC has conducted fate and transport modeling of soil, soil vapor, and groundwater during the project to assist in the evaluation of impacts to sensitive receptors, indoor air, aquifers, and off-site properties.