Dry Cleaners / Commercial Laundries

Dry Cleaners

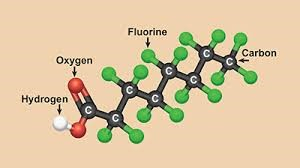

EEC Environmental’s (EEC) reputation for providing cost-effective environmental solutions for dry cleaners has made EEC the go-to choice for management companies, developers, and independent dry cleaner owners for over 20 years. The current and/or historic use of tetrachloroethene, better known as PCE or PERC, has negatively impacted most dry cleaner sites where it has been used; even when best available housekeeping and chemical storage practices have been implemented.

EEC prides itself on working with landowners, managers, and individual dry cleaner owners to evaluate potential contamination and provide remedies, when necessary, in a manner that allows business to continue uninterrupted so both the landowner and dry cleaner owner do not lose necessary revenue. When dealing with an operating dry cleaner, decisions cannot always be driven by environmental factors alone.

Each step needs to be a business decision that involves a smart environmental practice that is reasonable to the existing business model. For example, on a recent project, it was clear that the best remedial solution was to excavate shallow soils beneath the dry cleaner impacted by PCE; however, the business was still operating and could not afford to shut down to allow for excavation. Therefore, EEC installed a slab-slab depressurization system to eliminate the potential for vapor intrusion and subsequently performed the remedial excavation four months later in conjunction with already scheduled equipment upgrades.

EEC’s overall project goal in supporting the dry cleaning industry is smart, common-sense decisions that meet regulatory requirements that are manageable for the client.

Industrial Laundries

EEC Environmental (EEC) has extensive qualifications for engineering, environmental, and construction services for the industrial laundry industry. EEC has provided services to all the major laundry chains and many regional and independent industrial laundries. This significant presence in the industrial laundry industry has provided EEC an unparalleled ability to understand the needs, issues, and concerns in all aspects of the industry, including the acquisition of a new property or business, daily operation, permitting, compliance, construction, regulatory negotiations, litigation support, site investigation and remediation, and safety.

EEC Environmental has significant experience with the evaluation of industrial laundry facilities that have been impacted by petroleum, chlorinated solvents, and other contaminants. EEC performs a wide range of activities for the laundry industry, including Phase I Environmental Site Assessments (ESAs), compliance services, Phase II subsurface investigations, insurance cost-recovery, remedial services, regulatory negotiations, and litigation support. Further, EEC provides a broad base of general compliance services to the industrial laundry industry, including regulatory compliance, permitting, emergency business plans, emergency response, safety, Underground Storage Tanks (USTs) compliance, and state-specific compliance such as compliance with California’s SB989.

EEC’s Engineering and Construction divisions often combine to perform design-build projects for the industrial laundry industry predominately related to industrial wastewater treatment/compliance and equipment installations. These include dissolved air flotation systems, sludge dewatering systems, washers, dryers, boilers, heat exchangers, and chemical storage and delivery systems.

EEC has unique laundry wastewater consulting expertise and has helped more than 50 laundries achieve compliance with stringent sewer discharge limits (19 states nationally as well as international clients). This work includes negotiating reasonable compliance limits based on technically based arguments and reducing treatment costs or wastewater surcharges through chemical treatment adjustments. EEC also designed the Textile Rental Service Association (TRSA) Clean Green Program and performed a comprehensive water reuse study for a national chain.

EEC’s experience has included:

- Phase I Environmental Site Assessments (ESA) / Due Diligence

- Agency Negotiation

- Subsurface Investigation Involving Soil, Soil Vapor, and groundwater

- Fate & Transport Analysis

- Cost to Closure Evaluation

- Evaluation of Funding / Insurance for Remedial Actions

- Vapor Intrusion Evaluation

- Indoor Air Sampling / Air Quality Evaluation

- Stormwater Pollution Prevention Plan (SWPPP) for Construction or Facility Operations

- Subsurface Infrastructure Evaluation

- Permitting

- Facility Audits

- Community Engagement